SGD 340K Sold in Singapore & Malaysia since 1998

For Production ● Laboratory ● Cleanroom

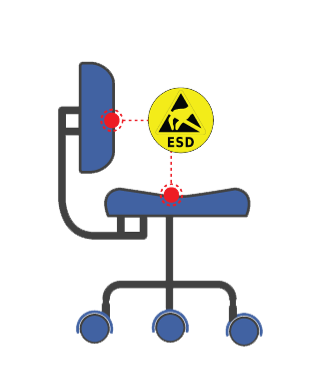

Get Fast Quotation for Cost-Cutting ESD Chair

The Benefits of TAKO’s ESD Chairs

Where the quality of ESD chair is reliable and not of your worry. Compliance, safety, durability, we got you covered

Compliance to ANSI ESD Standard

Our chairs meet all industry standards for electrostatic discharge protection.

High Quality Non-coated Casters

Durable casters designed for cleanroom environments without compromising mobility.

Durable & Stable Aluminum Chair Base

Built to last with high-quality materials that withstand daily use.

Ergonomic Design

Comfortable seating for long hours in production or laboratory environments.

The Foundation of a Safe & Productive Workspace

Discover ESD Chairs engineered for compliance, durability, and all-day operator comfort, delivered across Singapore.

Decades of Proven Trust

Since 1979, we’ve engineered ESD solutions that last. Our chairs are a cost-effective investment in long-term reliability and safety.

Audit-Ready & Compliant

Pass your facility audits with confidence. Every chair is designed to meet strict international ESD standards for a fully protected environment.

Local Expertise in Singapore

Our Singapore-based team provides fast delivery, expert consultation, and support to all major technology and business parks.

Engineered for Performance and Comfort

⚙️

Durable Construction

💺

Ergonomic Design

⚡

Certified Static Dissipation

Proudly serving facilities in Jurong, Tuas, Woodlands, Seletar, Changi Business Park, and across the island.

Upgrade Your Workspace Today

Protect your sensitive components and enhance operator productivity. Our experts are ready to help you find the perfect ESD chair for your needs.

Request a Quote & Consultation4 Solid Reasons Why You Should Buy ESD Chair From TAKO

In-house QC testing before delivery

Each and every Anti-Static chair is examined and carefully evaluated before we deliver to you. Each tested chair will be given a unique number for quality reference.

Conformity Report for ESD Chairs

Every purchase of TAKO’s ESD chairs will be issued a conformity report, being the result of testing and examination.

Complementary on-site Testing

Not sure how well is our chairs performing on your working site? We’ll come to you for a FREE testing.

In-House Assembled & Local Support

All chairs are assembled in our manufacturing plant. You can be sure to get our support over the ESD chairs whenever you need it.

Electrostatic Specifications

Your ESD chair says a lot about your production and working QUALITY.

Static Decay Time

Consistent surface to ground resistance reading

Electrostatic Discharge

Efficient electro-static discharge

Materials

Combined use of both conductive and static dissipative materials for optimal performance

Chair Types

Leather ESD Chair

Leather ESD Stool

PU ESD Chair

PU ESD Stool

Comfort & Safety in One

PU Seat Design

Durable and comfortable polyurethane seating.

Leather Seat Design

Premium leather option for enhanced comfort.

Metal Conductive Caster

Ensures proper grounding and smooth mobility.

Foot Ring for Drafting Chair

Added comfort for adjustable height chairs.

Trusted by Leading Companies in Singapore

“We’ve been using TAKO ESD chairs in our cleanroom for 5 years now. The quality is exceptional and their local support is unmatched.”

“The conformity reports provided with each chair give us peace of mind that we’re meeting all ESD standards in our lab environment.”

“TAKO’s on-site testing service helped us identify some grounding issues we didn’t know we had. Their expertise is invaluable.”

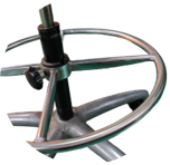

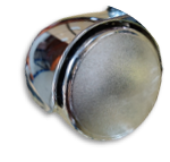

Patented ESD Chair Grounding Tools

Zap-Roller*

Meticulously designed mobile ESD grounder, enhance electrostatic grounding of your ESD chairs.

Zap-Cover*

Improve your worn ESD chair’s static discharge continuity at a cost saving approach.

Buy ESD chair and enjoy local services & supports

Our team will Respond Immediately

Or Get In Touch With Us Now

ESD Chair Ergonomics: Balancing Static Control and Comfort

In environments where electrostatic discharge (ESD) poses a risk to sensitive electronic components, an esd chair is not just a piece of furniture—it’s a critical tool. However, focusing solely on static control can overlook an equally important factor: worker comfort and ergonomics. A poorly designed esd chair, even if it offers excellent static dissipation, can lead to operator fatigue, discomfort, and reduced productivity. The true challenge lies in finding an esd chair that masterfully balances robust static control with sound ergonomic principles.

This balance is crucial because operators often spend long hours seated. An ergonomic esd chair supports proper posture, reduces strain, and enhances overall well-being, contributing to a more efficient and safer workspace. Let’s explore how these two vital aspects come together in a high-quality esd chair.

The Dual Mandate: Static Control Meets Ergonomic Design in an ESD Chair

An effective esd chair must perform two primary functions simultaneously:

- Preventing ESD Events: It must safely dissipate static charges from the operator to the ground, typically through conductive materials in the upholstery, chair components, and casters or glides, connecting to an ESD-safe floor or grounding cord.

- Ensuring Operator Comfort: It must provide adequate support for the body, allow for adjustments to fit various users, and promote healthy posture to minimize physical stress during prolonged sitting.

When selecting an esd chair, look for these features that combine ESD protection with ergonomic benefits:

- Conductive Materials: Upholstery (fabric or vinyl), casters/glides, and structural components designed to dissipate static effectively. Ensure they meet relevant ANSI/ESD standards.

- Adjustable Seat Height: Allows users to position their feet flat on the floor or footrest, with thighs parallel to the ground.

- Adjustable Backrest Height & Angle: Provides proper lumbar support and allows for dynamic sitting postures.

- Lumbar Support: A well-defined lumbar curve in the backrest supports the natural inward curve of the lower spine.

- Adjustable Armrests (Height, Width, Pivot): Support the arms and reduce strain on the shoulders and neck. Must also be ESD-safe if present.

- Seat Depth Adjustment: Ensures proper thigh support without pressing against the back of the knees.

- Durable Construction: High-quality components ensure longevity and consistent performance for both ESD and ergonomic features.

- Proper Grounding Path: A continuous path from the user, through the esd chair, to the ESD floor or grounding point.

Investing in an esd chair that excels in both areas yields significant advantages:

- Enhanced Product Protection: Reduced risk of ESD damage to sensitive electronic components, leading to lower defect rates.

- Improved Worker Productivity: Comfortable workers are more focused and efficient.

- Reduced Musculoskeletal Disorders (MSDs): Proper ergonomic support helps prevent back pain, neck strain, and other posture-related issues.

- Increased Operator Well-being: Greater comfort contributes to higher job satisfaction and morale.

- Compliance with Safety Standards: Meets industry requirements for both ESD protection and workplace ergonomics.

- Long-Term Cost Savings: Fewer product defects, reduced absenteeism due to discomfort, and higher productivity contribute to a better bottom line.

Impact of Proper ESD Control

(Industry estimates vary, illustrative figure)

Choosing the Right ESD Chair: Key Considerations

When investing in an esd chair, consider the specific tasks performed, the duration of use, and the characteristics of the users. Look for certifications (e.g., ANSI/ESD S20.20 compliance) and don’t hesitate to request demonstrations or trial periods. Training operators on how to properly adjust their esd chair is also vital to reap the full ergonomic benefits.

Ultimately, an esd chair is a specialized tool that plays a pivotal role in modern electronics manufacturing and assembly. By prioritizing both its static control capabilities and its ergonomic design, businesses can protect their products, empower their workforce, and foster a safer, more productive environment. The right esd chair is an investment in quality, efficiency, and employee well-being.

Ready to find the perfect esd chair solution that balances static control with superior ergonomics for your workspace? Explore our range of compliant and comfortable options!

Discover Our Other ESD Solutions in SingaporeESD Chair Maintenance: Cleaning Without Compromising Conductivity

An esd chair is a vital component in any Electrostatic Protected Area (EPA), safeguarding sensitive electronics from damaging static discharge. However, like any piece of equipment, it requires regular maintenance, including cleaning. The challenge? Cleaning an esd chair incorrectly can degrade its conductive properties, rendering it ineffective. This guide outlines how to clean your esd chair properly, ensuring it remains both hygienic and fully functional in its static control role.

Understanding the delicate balance between cleanliness and conductivity is key. Using the wrong cleaning agents or methods can introduce insulative residues or damage the specialized conductive materials incorporated into the esd chair design.

Why Proper Cleaning of Your ESD Chair Matters

Effective cleaning of an esd chair goes beyond mere aesthetics. It directly impacts:

- Sustained ESD Protection: Ensuring the chair's conductive pathways remain clear and effective.

- Longevity of the Chair: Preventing material degradation caused by harsh or inappropriate chemicals.

- Operator Health and Comfort: Maintaining a hygienic work environment.

- Compliance: Adhering to EPA maintenance protocols and industry standards for your esd chair.

Follow these do's and don'ts for routine esd chair care:

Do:

- Consult Manufacturer's Instructions: Always refer to the specific cleaning recommendations provided by your esd chair manufacturer first.

- Use Mild, ESD-Safe Cleaners: Opt for neutral pH cleaners, deionized water, or isopropyl alcohol (IPA) solutions (typically 70% IPA, 30% deionized water) for most surfaces.

- Use Soft, Lint-Free Cloths: Microfiber cloths are ideal to avoid scratching surfaces or leaving residues.

- Wipe, Don't Soak: Apply cleaner to the cloth, not directly onto the esd chair. Ensure surfaces are wiped and allowed to dry thoroughly.

- Clean Regularly: Establish a routine cleaning schedule based on usage and environment.

- Test Conductivity Periodically: After cleaning, and as part of regular maintenance, test the chair's resistance to ensure it's still within the specified ESD range.

Don't:

- Use Abrasive Cleaners or Tools: Avoid scouring powders, steel wool, or abrasive pads that can damage conductive surfaces.

- Use Harsh Solvents: Steer clear of bleach, ammonia-based cleaners, strong acids, or alkaline detergents unless explicitly approved for your specific esd chair material.

- Use Cleaners with Silicones or Insulative Residues: Many common furniture polishes or protectants can leave an insulative film.

- Saturate the Chair: Excessive moisture can damage internal components or take too long to dry.

The choice of cleaning agent is critical for an esd chair. Here’s a breakdown:

- Deionized (DI) Water: Excellent for light soiling. It cleans without leaving conductive or insulative residues.

- Isopropyl Alcohol (IPA): Effective for disinfection and removing some types of contaminants. Use in appropriate concentrations (e.g., 70% IPA/30% DI water). Pure IPA can sometimes be too harsh for certain plastics or vinyls over time.

- Neutral pH ESD-Safe Cleaners: Specifically formulated cleaners designed for ESD-safe surfaces. These are often the best choice as they are tested for compatibility with conductive materials used in an esd chair.

- Vinyl/Fabric Specific Cleaners: If your esd chair has conductive fabric or vinyl, there might be specialized cleaners recommended. Some conductive fabrics may require periodic treatment with a topical antistat to refresh their properties, but this should be guided by the manufacturer.

- Conductive Waxes/Polishes (Use with Caution): Some manufacturers might recommend specific conductive polishes for hard surfaces to maintain or enhance conductivity. Only use products specified for your esd chair.

Always test a cleaner on a small, inconspicuous area of the esd chair first to ensure no adverse reaction before cleaning the entire chair.

Cleaning Agents: The Good & The Bad for Your ESD Chair

- Deionized Water

- Isopropyl Alcohol (70% Solution)

- Neutral pH ESD-Safe Cleaners

- Manufacturer-Approved Products

- Abrasive Powders/Pads

- Bleach / Ammonia

- Strong Solvents (Acetone, MEK)

- Silicone-based Polishes

Benefit: Sustained ESD Protection

Testing Conductivity After Cleaning Your ESD Chair

After cleaning and allowing the esd chair to dry completely, it's good practice to verify its conductivity. Use an ESD surface resistivity meter to check key areas like the seat, backrest, and ensure a proper path-to-ground (often through the casters to an ESD floor or via a grounding cord). This confirms that your cleaning process hasn't inadvertently compromised the chair's static dissipative capabilities.

By following these guidelines, you can ensure your esd chair remains a clean, comfortable, and, most importantly, effective tool in your static control program. Regular and correct maintenance of your esd chair is an investment in product quality and workplace safety.

Need expert advice on maintaining your esd chair or looking for approved cleaning supplies? We're here to help!

Get Local Support from TAKO in SingaporeCan You Retrofit Non-ESD Chair Armrests to Be Static-Safe?

When aiming for a comprehensive Electrostatic Protected Area (EPA), every component matters. If you have existing standard chairs, you might wonder if their non-ESD armrests can be retrofitted to meet static-safe requirements, potentially saving costs on a new esd chair with armrest. While technically possible in some cases, it’s a path fraught with challenges and requires careful consideration to ensure genuine, reliable ESD protection.

The primary issue with standard armrests is that they are typically made from insulative materials like standard plastics or polyurethane, which can accumulate and hold static charges. An esd chair with armrest designed from the ground up uses inherently static dissipative or conductive materials throughout the armrest structure and ensures a path to ground.

The Core Challenge: Achieving True and Lasting Conductivity

Retrofitting armrests on a non-ESD chair to make them static-safe involves modifying or replacing parts to ensure they can dissipate static charges effectively. This isn't just about surface treatment; it's about creating a continuous and reliable grounding path from the armrest surface through the chair and to ground. A purpose-built esd chair with armrest is engineered with this entire system in mind.

Several approaches might be considered for retrofitting armrests on a non-esd chair:

- Conductive Sprays or Coatings:

Applying a layer of conductive paint or spray can provide temporary surface conductivity. However, these coatings can wear off with use, get scratched, or be affected by cleaning agents, compromising their effectiveness over time. Durability is a major concern.

- ESD-Safe Covers or Sleeves:

Custom-made or off-the-shelf conductive fabric/vinyl covers can be fitted over existing armrests. The key challenge is ensuring a consistent and reliable electrical connection from the cover, through the chair's grounding mechanism (if it even has one that can be adapted), to the ground. Simply covering an insulative armrest doesn't guarantee safety if the charge has no path to dissipate.

- Replacing Arm Pads with ESD-Safe Versions:

If the armrest design allows, it might be possible to replace the existing insulative arm pads with ones made from ESD-safe materials. This is often the most reliable retrofit method for the arm pads themselves, but you must still ensure the armrest frame and its connection to the chair base also form part of the ground path. This is often where a full esd chair with armrest excels, as the entire structure is designed for this.

- Adding Grounding Straps or Wires:

This involves physically attaching grounding straps from the armrest surface to the chair's main grounding point. While it can create a path, it can be unsightly, prone to damage, and may not provide uniform protection across the entire armrest surface. It can also introduce snag hazards.

Retrofit Method: Feasibility & Reliability

Note: Reliability heavily depends on proper implementation and ongoing testing.

Crucial Checks for Any Retrofit

- Material Compatibility: Ensure chosen method doesn't damage armrest.

- Durability: Will the solution withstand daily wear, tear, and cleaning?

- Consistent Ground Path: Is there a reliable electrical path from armrest surface to ground?

- Thorough Testing: Verify resistance (RTT, RTG) to ANSI/ESD S20.20 or relevant standards.

Why a Purpose-Built ESD Chair with Armrest is Often Better

While retrofitting might seem like a cost-saver, it often falls short in terms of reliability, durability, and guaranteed compliance compared to a new, purpose-built esd chair with armrest. These chairs are:

- Engineered for ESD Safety: All components, including armrests, are made from appropriate static dissipative or conductive materials.

- Integrated Grounding: The path to ground is designed into the chair's structure, ensuring consistent performance.

- Tested and Certified: Reputable manufacturers provide chairs that meet industry standards like ANSI/ESD S20.20.

- Durable: ESD properties are inherent to the materials, not just a surface treatment, ensuring longevity.

Conclusion: Weighing Risks and Benefits

Retrofitting non-ESD armrests to be static-safe is a complex task. While minor modifications *might* offer some improvement, achieving reliable, long-term ESD protection that meets industry standards is difficult and often impractical. The risk of an ineffective retrofit leading to ESD damage can outweigh any initial cost savings. For critical applications, investing in a properly designed and certified esd chair with armrest is generally the most prudent and effective solution to ensure robust static control in your EPA.

ESD Gaming Chairs with Armrests: Do They Actually Work?

The world of gaming peripherals is ever-expanding, and recently, "ESD gaming chairs" have started appearing on the market. Promising the ergonomic comfort and style of a high-end gaming chair along with protection against electrostatic discharge (ESD), they seem like an ideal solution for gamers with expensive PC components or sensitive home electronics. But the critical question remains: does an esd chair with armrest marketed for gaming truly provide effective static protection?

Traditional ESD chairs are staples in electronics manufacturing and labs, built to stringent standards. When these principles are applied to gaming chairs, understanding what makes them genuinely "ESD-safe" versus just a marketing buzzword is crucial, especially concerning all points of contact, including the armrests.

The Allure: Why Consider an ESD Gaming Chair with Armrest?

The appeal is clear: merge the often superior comfort, adjustability, and aesthetics of modern gaming chairs with the functional necessity of ESD protection. For streamers, dedicated gamers, or hobbyists working with electronics at their gaming setup, safeguarding thousands of dollars in equipment from an unseen zap is a compelling proposition. An esd chair with armrest designed for this purpose aims to be that perfect hybrid.

Before trusting an ESD gaming chair, especially an esd chair with armrest components, consider these critical elements:

- Material Integrity: Are the upholstery, armrest pads, and other contact surfaces made from genuinely static dissipative or conductive materials? Standard plastics and fabrics used in many gaming chairs are insulative.

- Continuous Grounding Path: ESD protection relies on a continuous path from the user, through the chair (including seat, back, armrests, gas lift, base), to conductive casters or a grounding cord connecting to an ESD-safe floor or common point ground. This entire system must be designed to dissipate static.

- Verified Performance & Standards: Does the manufacturer provide test data or certification to recognized ESD standards (e.g., ANSI/ESD S20.20, IEC 61340-5-1)? Vague claims without substantiation are a red flag. An esd chair with armrest needs its armrests tested as part of the system.

- Durability of ESD Properties: How long will the chair's ESD features last under typical, often intensive, gaming use? Surface treatments can wear off, unlike inherently dissipative materials.

ESD Performance Spectrum (Illustrative)

Note: This is illustrative. Actual ESD effectiveness varies greatly by specific model, materials, and adherence to standards. Always verify manufacturer claims.

Critical ESD Features Checklist

- Conductive/Dissipative Upholstery: Fabric and padding designed to prevent static build-up.

- Grounded Armrests: Armrests on an esd chair with armrest must be part of the ground path.

- ESD-Safe Casters/Glides: Essential for dissipating charge to an ESD floor.

- Verified Path-to-Ground: The entire chair must be tested for electrical continuity to ground.

The Verdict: Do ESD Gaming Chairs *Actually* Work?

The answer is nuanced: some can, but many might not meet true industrial ESD standards. A well-designed ESD gaming chair that uses appropriate materials, ensures a continuous ground path (including through its armrests), and ideally has been tested to relevant standards, *can* provide a valuable level of protection for a home gaming or hobbyist setup. Such an esd chair with armrest features could indeed safeguard your sensitive electronics.

However, be wary of chairs making vague "ESD-safe" claims without transparent specifications or test results. These may offer little more protection than a standard gaming chair. For professional EPA environments, a certified industrial ESD chair remains the benchmark. For dedicated gamers looking to protect their investment, thorough research into the specific esd chair with armrest model is paramount.

Curious about what defines genuine ESD protection in seating? Don't leave your valuable gear to chance!

WhatsApp Now & Explore True ESD Chair Solutions in SingaporeCan ESD Office Chairs Double as Ergonomic Task Chairs?

In modern workplaces where sensitive electronics are handled, the need for static protection is paramount. This often leads to the adoption of specialized equipment, including esd office chairs. Simultaneously, employee well-being and productivity are increasingly linked to ergonomic workspace design. This raises a pertinent question: can esd office chairs effectively serve the dual purpose of providing robust static control *and* the comprehensive ergonomic support expected from a high-quality task chair?

The short answer is a resounding yes, provided they are designed thoughtfully. A well-engineered esd office chairs doesn't have to compromise on ergonomics. In fact, for environments where personnel are seated for extended periods, combining these functionalities is not just a convenience, but a necessity for optimal performance and safety.

Understanding the Core Functions

An esd office chairs is primarily designed to prevent electrostatic discharge by safely dissipating static charges from a person to ground. This involves conductive materials in the upholstery, casters, and internal components. An ergonomic task chair, on the other hand, focuses on supporting the human body correctly to reduce strain, promote good posture, and enhance comfort during long work hours.

For an esd office chairs to also be a great ergonomic chair, it must include:

- Adjustable Seat Height: To suit various user heights and desk setups.

- Proper Lumbar Support: Adjustable or inherently contoured to support the lower back's natural curve.

- Adjustable Armrests: Height, width, and pivot adjustments to support arms and reduce shoulder strain (must also be ESD-safe).

- Seat Depth Adjustment: Allowing users to sit comfortably with proper thigh support.

- Backrest Angle Adjustment: Enabling recline and dynamic movement.

- Quality Cushioning: Providing comfort without sacrificing ESD properties.

- Swivel and Smooth Casters: For ease of movement (casters must be conductive).

While incorporating ergonomic features, the primary ESD function of the esd office chairs must not be compromised:

- Consistent Conductivity: All ergonomic components (levers, mechanisms) must not interrupt the path to ground.

- ESD-Safe Materials: Upholstery, arm pads, and casters must be made from static dissipative or conductive materials meeting standards like ANSI/ESD S20.20.

- Reliable Grounding Path: From the user contact points, through the chair structure, to conductive casters or a grounding drag chain/cord.

- Durability of ESD Properties: Materials must maintain their static control properties throughout the chair's lifespan and typical use.

The Ideal Convergence: ESD & Ergonomics

True dual-functionality lies in the seamless integration of both critical aspects.

Dual-Benefit Checklist: What to Look For

- Certified ESD Materials: Upholstery & components.

- Full Adjustability: Seat, back, arms, lumbar.

- Conductive Casters/Glides: Verified ground path.

- Durable, Comfortable Padding: Supportive for long hours.

- Reputable Manufacturer: Clear specifications & testing.

Benefits of High-Quality Dual-Function ESD Office Chairs

Investing in esd office chairs that also excel ergonomically offers significant advantages:

- Enhanced Productivity: Comfortable workers are more focused and efficient.

- Reduced Health Risks: Proper ergonomic support minimizes musculoskeletal issues, while ESD protection safeguards products and equipment.

- Cost-Effectiveness: One chair serves two critical functions, potentially reducing the need for separate specialized seating.

- Improved Employee Morale: Providing comfortable and safe equipment shows commitment to employee well-being.

- Streamlined EPA Management: Standardizing on chairs that meet both needs simplifies procurement and compliance.

Conclusion: A Smart Investment for Modern Workspaces

Modern esd office chairs absolutely can, and should, double as effective ergonomic task chairs. The key is to select models from reputable manufacturers who prioritize both aspects in their design and material selection. By looking for chairs that meet relevant ESD standards and offer comprehensive ergonomic adjustability, businesses can create workspaces that are safe for sensitive electronics, and healthy and productive for their employees. This dual approach is not a compromise but an intelligent synergy for today's technologically advanced office environments.

Looking for esd office chairs that don't compromise on comfort or protection? Discover solutions that offer the best of both worlds.

Get Cost-Cutting ESD Chair Solutions in SingaporeESD Chair Warranties: What’s Really Covered?

When investing in esd office chairs for your workplace, the warranty is more than just a piece of paper; it's an assurance of quality, durability, and, crucially, sustained performance of its static control properties. However, not all warranties are created equal, and understanding the fine print is vital to ensure you're getting the protection you expect for your esd office chairs.

A comprehensive warranty for an esd office chairs should ideally cover both the standard chair components (structural integrity, mechanisms) and, very importantly, the ESD-specific features that differentiate it from regular seating. Let's delve into what you should typically look for and be aware of.

Deconstructing the Warranty for ESD Office Chairs

Most chair warranties are multi-faceted, often with different coverage periods for various parts of the chair. For esd office chairs, this can be even more specific.

A good warranty for esd office chairs often includes:

- Structural Components: This usually has the longest coverage, covering the frame, base, and other non-moving structural parts against defects in materials and workmanship.

- Chair Mechanisms: Tilt mechanisms, gas lifts (pneumatic cylinders), and adjustment levers are typically covered for a moderate period.

- Casters and Glides: Should be covered against breakage under normal use (for esd office chairs, ensure conductive casters are specified).

- Upholstery: Fabric or vinyl may have a shorter warranty, covering seams and wear under normal conditions. ESD-specific fabrics/vinyl must maintain their conductive properties.

- ESD Properties: This is CRITICAL. The warranty should explicitly state coverage for the chair's ability to meet specified ESD resistance ranges (e.g., ANSI/ESD STM12.1). This is what makes it an esd office chairs.

Be aware of what's often NOT covered or has limitations:

- Normal Wear and Tear: Scuffs, fading, or minor pilling of fabric over time are generally not covered.

- Misuse or Abuse: Damage resulting from improper use, accidents, alterations, or failure to follow maintenance guidelines.

- Damage from Incorrect Cleaning: Using harsh or non-approved cleaners that degrade ESD properties or materials.

- Labor Costs: Some warranties cover parts only, not the labor to install them.

- Consequential Damages: Damage to other equipment (e.g., sensitive electronics) if the chair fails is rarely covered directly by the chair warranty itself. This highlights the importance of choosing a reliable esd office chairs.

- Non-Transferable: Warranties are usually only for the original purchaser.

Warranty Watchlist: Key Questions

- Is there a specific guarantee for maintaining ESD resistance levels over time?

- What is the claim process? Is it straightforward and well-documented?

- Are there separate warranties for different components of the esd office chairs?

- What maintenance is required to keep the warranty valid, especially for ESD properties?

The Importance of the ESD Performance Warranty

For esd office chairs, the warranty on its static dissipative properties is paramount. This part of the warranty ensures the chair will continue to perform its primary function of protecting sensitive electronics. Look for clear statements about the resistance range (e.g., surface resistance, resistance to ground) and the duration for which these properties are guaranteed under normal use and proper maintenance.

Conclusion: Read Carefully, Choose Wisely

A warranty is a key indicator of a manufacturer's confidence in their esd office chairs. Don't just glance at the overall "years covered"; dig into the details, especially concerning the ESD-specific elements. A robust and clear warranty, particularly one that backs up the chair's static control performance, offers peace of mind and protects your investment in maintaining a safe and effective Electrostatic Protected Area (EPA).

Have questions about warranties for esd office chairs or need help finding chairs with reliable coverage? We can assist!

WhatsApp Now to Know About ESD Chair WarrantyESD Lab Chairs for Cleanrooms: Static Control vs. Particulate Shedding

Selecting seating for controlled environments like cleanrooms presents a unique challenge. Not only must these chairs prevent electrostatic discharge (ESD) to protect sensitive components, but they also need to meet stringent cleanliness standards by minimizing particulate generation. This dual requirement means that standard esd lab chairs may not be suitable, and specialized cleanroom-compatible esd lab chairs are essential.

The core issue lies in balancing effective static control with materials and construction techniques that do not shed particles, which could contaminate the cleanroom environment. This balance is critical in industries such as semiconductor manufacturing, pharmaceuticals, biotechnology, and aerospace.

The Intricate Demands: ESD and Cleanliness

An esd lab chairs for cleanroom use must simultaneously address two distinct but equally important concerns. Failure in either aspect can lead to product defects, compromised research, or safety hazards.

Cleanrooms are classified according to the number and size of particles permitted per volume of air (e.g., ISO 14644-1 standards). Common classes include ISO Class 3 through ISO Class 8 (lower number means cleaner).

- Particulate Sources: People are a major source of contamination. Equipment, including chairs, can also shed particles from upholstery, lubricants, and moving parts.

- Material Choice: Materials used in esd lab chairs for cleanrooms must be non-shedding, non-outgassing, and easy to clean.

- Construction: Seams, crevices, and mechanisms must be designed to minimize particle entrapment and generation.

A true cleanroom esd lab chairs integrates specific design features:

- Non-Shedding Upholstery: Typically smooth, durable materials like specialized vinyl or polyurethane that resist particle generation. Some ESD fabrics with tight weaves might be suitable for less stringent cleanroom classes.

- Sealed Edges & Seams: To prevent particle release from within the cushioning.

- Enclosed Mechanisms: Gas lifts and adjustment mechanisms should be covered or sealed.

- HEPA Filtration (in some models): Some advanced esd lab chairs may incorporate filtration systems within the seat to capture particles.

- Conductive, Non-Marking Casters: Must be suitable for cleanroom floors and provide a reliable path to ground.

- Chemical Resistance: Materials should withstand common cleanroom cleaning agents without degrading or increasing particulation.

- Verified ESD Performance: Meeting standards like ANSI/ESD S20.20 for resistance and static decay.

Cleanroom ESD Lab Chair: Dual Imperatives Meter

Both properties are non-negotiable for qualifying esd lab chairs in cleanroom applications.

Material Suitability Guide for ESD Lab Chairs

Making the Right Choice for Your Controlled Environment

When selecting esd lab chairs for a cleanroom, always verify the chair's specifications against your specific cleanroom class (e.g., ISO 5, ISO 7) and ESD control program requirements. Look for manufacturers who provide clear data on particulate testing and ESD compliance. Ergonomics, while secondary to these critical functions in this context, should still be considered for operator comfort and productivity, especially if the esd lab chairs will be used for extended periods.

Ultimately, investing in the correct cleanroom-compatible esd lab chairs is crucial for maintaining product integrity, ensuring reliable research outcomes, and upholding the stringent operational standards of any controlled environment.

Navigating the complexities of cleanroom and ESD requirements? Find specialized esd lab chairs designed for the most demanding environments.

Get ESD Lab Chairs in Singapore from Local SupplierWhere to Buy ESD Chairs in Singapore: Local Suppliers vs. Imported Options

Finding the right ESD chairs, including specialized esd lab chairs, in Singapore involves a key decision: should you source from local suppliers or explore direct import options, such as those found on large online marketplaces like Alibaba? This choice significantly impacts lead times, warranty, after-sales support, and, crucially, compliance with local standards like Singapore Standard SS 638 for ESD protection.

While imported options might initially seem more cost-effective, a deeper look reveals that local distributors, such as established companies like TAKO (as an example of a local player), often provide a more comprehensive and reliable solution, particularly for businesses requiring certified esd lab chairs and adherence to stringent quality controls.

The Procurement Dilemma: Local Expertise vs. Global Marketplaces

Navigating the options for acquiring ESD chairs, whether for general office use in an EPA or specific esd lab chairs for controlled environments, requires careful evaluation of several critical factors.

Consider these points before making your purchase decision for any type of ESD seating, including esd lab chairs:

- Lead Times & Availability:

Local: Typically shorter lead times, faster delivery, and readily available stock for common models.

Imported: Can involve lengthy shipping times (weeks or months), potential customs delays, and unpredictable stock levels. - Warranty & After-Sales Support:

Local: Offer clear warranty terms, accessible local support for repairs, replacements, and maintenance. Face-to-face interaction is possible.

Imported: Warranty claims can be complex, costly to ship items back, and support may be unresponsive or non-existent. - Compliance with SS 638 & Other Standards:

Local: Reputable local suppliers are more likely to offer products tested and certified to Singapore Standard SS 638 and other relevant international standards (e.g., ANSI/ESD S20.20). They understand local requirements for esd lab chairs and other sensitive applications.

Imported: Compliance claims might be unverified or self-declared. Ensuring products meet specific local standards like SS 638 can be challenging. - Product Quality & Customization:

Local: Often provide higher quality, tested products. May offer customization options (e.g., specific fabrics, armrests, heights for esd lab chairs) and expert advice.

Imported: Quality can be inconsistent. What You See Is Not Always What You Get (WYSIWYG). Customization is often limited or requires large minimum orders. - Consultation & Expertise:

Local: Can provide on-site assessments, expert advice on EPA setup, and recommend the most suitable chairs for your specific needs, including the demanding requirements for esd lab chairs.

Imported: Typically a transactional purchase with little to no expert consultation.

Local Singapore Suppliers vs. Direct Import: Key Differentiators

Local Singapore Suppliers (e.g., TAKO)

Direct Import / Online Marketplaces (e.g., Alibaba)

Note: Percentages are illustrative, representing general likelihood or quality levels.

Focus: SS 638 Compliance

Ensures your ESD chairs, including specialized esd lab chairs, meet Singapore's safety and performance benchmarks.

The Importance of SS 638 Compliance in Singapore

Singapore Standard SS 638 (Code of practice for the control of undesirable static electricity) provides guidelines for establishing and maintaining ESD control programs. Sourcing esd lab chairs and other ESD equipment that aligns with SS 638 ensures that your investments contribute effectively to your overall static control strategy and meet local expectations for safety and performance. Reputable local suppliers are typically well-versed in these standards and can provide products that demonstrably comply.

Making an Informed Decision for Your Business

While the allure of lower upfront costs from direct imports is understandable, businesses in Singapore, especially those handling high-value or highly sensitive components requiring esd lab chairs, should weigh the long-term benefits of partnering with established local suppliers. The assurance of quality, compliance (particularly with SS 638), reliable warranty, accessible after-sales service, and expert local advice often provides far greater value and peace of mind.

Looking for reliable ESD chairs in Singapore that meet local standards? Connect with experts who understand your needs.

Find Local ESD SolutionsESD Lab Chairs for Cleanrooms: Static Control vs. Particulate Shedding

In the high-stakes environment of cleanrooms, particularly within Singapore's advanced manufacturing and research sectors, the choice of equipment is paramount. Lab chairs are no exception. They must not only provide effective electrostatic discharge (ESD) protection but also adhere to stringent cleanliness standards by minimizing particulate generation. Standard ESD chairs often fall short, necessitating specialized esd safe chairs in Singapore designed for cleanroom compatibility.

The challenge is a delicate balancing act: ensuring robust static control while using materials and construction that prevent the shedding of particles. This is crucial for industries relying on pristine environments, as even minute contamination from esd safe chairs in Singapore can impact product yields or research integrity.

The Dual Imperative: Why Both ESD Control and Low Particulation Matter

Cleanroom lab chairs face a double mandate. ESD protection safeguards sensitive electronic components from static damage. Simultaneously, low particulate generation is vital to maintain the cleanroom's air quality and prevent contamination of products or processes. For businesses in Singapore sourcing esd safe chairs in Singapore, understanding this dual need is key.

Cleanrooms operate under strict ISO classifications (e.g., ISO Class 5 to ISO Class 8), dictating permissible particle counts. Personnel and equipment are primary sources of these particles. Importantly:

- Particle Attraction: Static charges on surfaces, including those on inadequately grounded chairs, can act like magnets, attracting and holding airborne particles. This can concentrate contaminants in critical areas.

- Material Constraints: Many standard fabrics or chair components, even if ESD-safe, may shed fibers or particles unsuitable for cleanroom use. This makes selecting appropriate esd safe chairs in Singapore more complex.

- Operational Protocols: Proper grounding of all equipment, including chairs, is fundamental in both ESD control and minimizing static-induced particle attraction.

When seeking esd safe chairs in Singapore for cleanroom use, look for these specific characteristics:

- Non-Shedding & Sealed Upholstery: Materials like specialized cleanroom-grade vinyl or polyurethane are preferred. Seams must be sealed or minimized to prevent particle escape from cushioning.

- Enclosed & Smooth Mechanisms: Adjustment levers, gas lifts, and other moving parts should be covered or designed to prevent particle generation and entrapment.

- Conductive Cleanroom Casters/Glides: These must be non-marking, suitable for cleanroom flooring, and provide a reliable path-to-ground.

- Chemical Resistance: The chair materials must withstand rigorous cleaning and disinfection protocols common in cleanrooms without degrading or increasing particulation.

- Verified ESD Performance: Compliance with standards like ANSI/ESD S20.20 is essential for all esd safe chairs in Singapore, ensuring proper resistance and static decay characteristics.

- Optional Filtration: For very high-grade cleanrooms, some chairs incorporate internal HEPA filtration for particle capture at the source.

Cleanroom Chair: Essential Compliance Pillars

Both are non-negotiable for qualifying esd safe chairs in Singapore for cleanroom applications.

Key Cleanroom ESD Chair Features

- Non-Shedding & Sealed Materials (Vinyl/PU)

- Enclosed/Covered Mechanisms

- Conductive Cleanroom-Grade Casters

- Verified ANSI/ESD S20.20 Compliance

- Resistance to Cleanroom Cleaning Agents

Selecting the Right ESD Safe Chairs in Singapore for Your Cleanroom

Choosing appropriate esd safe chairs in Singapore demands careful matching of the chair's specifications to your facility's specific cleanroom ISO class and your comprehensive ESD control program. Prioritize suppliers who offer transparent data on particulate testing, material composition, and ESD compliance. While ergonomics are important for operator comfort, the primary considerations for cleanroom esd safe chairs in Singapore must be static control and particulate minimization.

A meticulous approach to selecting these specialized chairs is an investment in protecting sensitive products, ensuring the reliability of research, and maintaining the highest operational standards in controlled environments across Singapore.

Ensure your cleanroom meets the highest standards. Find specialized esd safe chairs in Singapore designed for demanding applications.

Discover ESD Office Chairs in Singapore